In Part 1 in the December 2011 issue, I outlined the basic operating principles of Hydro-lectric systems, which were used by several automobile manufacturers during the1940s. Essentially, the Hydro-lectric system was an early version of power windows, seat and top which utilized a pump and reservoir containing (originally) brake fluid, a closed loop of metal lines and flexible hoses, hydraulic pistons, switches, springs, and solenoids to operate the various components.

In this second, and final, installment, I’d like to outline various trouble-shooting and testing procedures, and touch upon more technical aspects of the system. First, check the battery. For efficient operation, battery gravity reading should not be less than 1200 or equivalent voltage. In laymen’s terms, be sure the battery is fresh and fully charged. In some cases, a slightly discharged battery may be sufficient to run the hydraulic motor, but not sufficient to operate the power cylinder solenoids also. Hence, the complete system will not operate.

Next, check the fluid level in the pump reservoir. Typically, there is a line stamped into the front of the reservoir canister indicating the proper fluid level. Important note: When checking the fluid level in the pump reservoir, be sure all the windows are lowered, the top on convertibles should be down, and the front seat should be in a full rearward position! Failure in the electrical system, aside from a low battery, may be due to any number of causes such as loose wiring terminals, “grounds,” “shorts,” broken wire(s), or inoperative solenoids or switches.

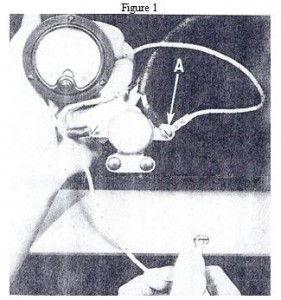

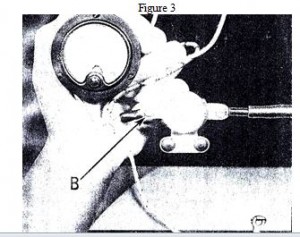

There should be a solenoid, usually mounted on the firewall near the pump. To determine if current is reaching the circuit breaker, connect the positive lead of a tester to the power source terminal “A” of the circuit breaker and the negative lead to a good ground, as shown in Figure 1 on the next page. A current flow should register on the tester. If not, check the wire from the power source for a break or a short. In some cases, failure of the hydraulic motor to start may be caused by an inoperative motor solenoid switch.

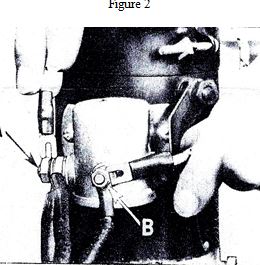

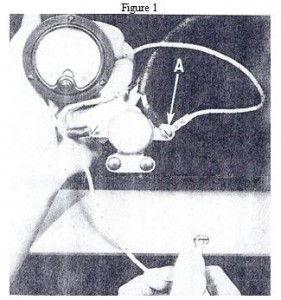

To check the operation of this solenoid, connect one end of a jumper wire to the battery wire terminal “A” and the other end to the switch wire, terminal “B,” as shown below in Figure 2. If the switch is operating satisfactorily a “click” will be heard and the battery to motor circuit will be closed, starting the motor. If no “click” is heard, the solenoid should be replaced.

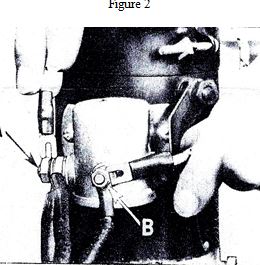

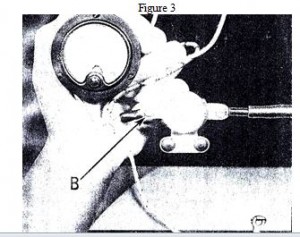

Next, to determine if the circuit breaker is operating, connect the positive lead of the tester to the switch feed wire terminal “B” of the circuit breaker and ground the negative lead, as shown below in Figure 3.

A current flow should register if the circuit breaker is operating. Sometimes, the power window, or power seat, switch may be at fault. On the back of the switch, using an individual window switch as an example, will be three terminals. These terminals will be marked “BAT” (battery), “MOT” (motor), and “CYL” (cylinder). The center terminal is typically the “battery,” or feed, terminal. You can test the operation of the switch by disconnecting the wires and using a simple ohmmeter. Place the 2 leads of the ohmmeter between the “BAT” and “MOT” terminals and push the toggle switch in the upwards position. If the switch is okay, you should get a reading on the ohmmeter. Use the same procedure to check for continuity between the “BAT” and the “CYL” terminals. Another simple way of testing the switch, with all wires connected, is to place a jumper wire between the “BAT” and “MOT” terminals. If the circuit and switch are okay, the hydraulic motor should start. When placing the jumper wire between the “BAT” and “CYL” terminals, you should hear a distinctive “click”, which is the cylinder solenoid operating.

As with most everything made in “the good old days,” these switches can be disassembled for cleaning or repair. They are basically a toggle with return springs and copper contacts. If the spring(s) or toggle assembly are not broken, you can usually restore these switches to operating condition simply by cleaning the copper contacts using 600 grit wet/dry silicon carbide sandpaper or a good commercial electrical contact cleaner.

In addition to the electrical system, it is imperative that all windows, power seat, and convertible top mechanisms operate freely by hand with no binding or obstructions. Clean and lubricate (I use white lithium grease) all pivot points on the frameworks containing the hydraulic cylinders, seat tracks on power seats, and pivot points on the convertible top. Inspect the mohair-lined U-shaped channels in which the window glass rides and replace if worn or damaged.

Finally, on convertibles only, there is an additional component I refer to as the power top control switch. This is a Bakelite unit mounted on the firewall with two wires attached to terminals, and fittings with metal lines attached. The top portion of this switch is attached to the “power top” operating knob and lever, which goes through the firewall and is attached to the bottom of the dash with a mounting bracket. When you “PULL” this rod, it rotates the top portion of the Bakelite unit. Inside this unit are return springs, a circular copper contact plate, and ports. When you “PULL” or “PUSH” the power top control rod, the upper portion of the Bakelite switch rotates, completing the electrical circuit and starting the hydraulic motor. At the same time, the appropriate ports inside the unit are uncovered, thus diverting the fluid to either raise, or lower, the top. This Bakelite switch can also be disassembled for cleaning, and can usually be restored to operating condition as long as the Bakelite housing isn’t broken.

So there you have it. What seems like a complicated system is actually quite simple when broken down into its individual components. New cylinders, hoses, Hydro-lectric motor and top control switch rebuilding, and expert technical advice are readily available from Hydro-E-Lectric in Punta Gorda, Florida by calling (800)343-4261. They are very knowledgeable and wonderful people to deal with!

newsletter