by Art Gardner

If, like lots of us, you don’t have a steering wheel puller, I’ve come up with another, if not better, way to remove your steering wheel. Besides doing away with the need for a puller, this method spares the horn button contact from possible damage.

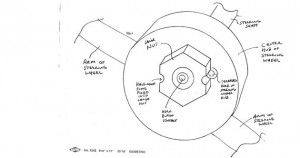

Refer to the drawing below, which shows the top of the steering wheel after the horn button is removed. First, remove the large nut which holds the wheel. Using a small diameter round file (no, not the trash can), file “half-moon” slots into the middle of two opposite sides of the nut to line up with the threaded holes in the hub of the steering wheel.

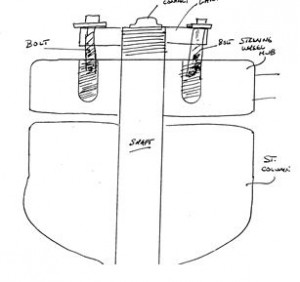

Now, refer to the drawing on the next page. Go to a hardware store or other supplier of fasteners which sells 3/8-16 “washer-head” bolts, sometimes referred to as washer-head screws. (These are bolts or screws with an integral built-in washer as part of the bolt head.) I suggest that you buy 6 such bolts: 3 pairs or 2 each, in lengths of ¾ inch, 7/8 inch and 1 inch (1.9, 2.2 and 2.5 cm.), if available. You can see two of them in the drawing.

As shown in the drawing below, loosely screw on the large steering wheel hold-down nut the until most or all of its threads have engaged the steering shaft, but with some space still remaining between the bottom of the nut and the steering wheel hub. At the same time, make sure the two “half-moon” slots are lined up with the threaded holes in the steering wheel hub. Then, starting with the 1 inch pair, screw two of the washer-head bolts past the “half-moon” slots and into the threaded holes in the steering wheel hub until the washer heads are snug against the large steering wheel nut.

Now, using a wrench, slowly and carefully tighten the washer-head bolts, each one a fraction of a turn at a time, so that neither bolt puts more pressure on the nut than the other. Advantageously, this works by putting force on the large threads of the steering column shaft, instead of on the end of the shaft (where it could damage the horn contact).

As I did, you may find that you will have to exchange the first pair of washer-head bolts for a shorter pair as the steering wheel is pulled up. You may also find that you’ll have to unscrew the large steering wheel nut one or more turns to create more space between it and the steering wheel hub. When the steering wheel breaks loose, you may or may not hear a snapping or popping noise. Like the 3 guys lowering the engine in the factory photo on page 3, “Easy does it”