Thanks to Dan we have this index. It was a great help putting this site together. I suggest copying this off to a Word document where you can search for particular text. You can also do a search on this page as well holding down the Ctrl key and f key then typing in what you are searching for.

’49 TIMES TECHNICAL ARTICLE INDEX: MARCH 2001 – MARCH 2010

By Dan Fisher

March 2001: Did You Know? Production Numbers For 1949; First Aid For Fog Lights.

June 2001: Radial Wide Whitewalls For Your ‘49? Did You Know?…1949 Convertibles.

September 2001: To Plate Or Not To Plate: Headlight Rims/Bezels; Tech Tip: Check Your Battery;

Forty Nine Fastener Fun: Club Coupe (Fastback) Rear Window Removal; Drooping Door Handles (Again).

December 2001: How To Take Out Your 1949 Radio.

March 2002: Tracing Turn Signal Wires; Your Shock Absorbers; Rebuilding The Rear Stabilizer;

’49 And ’50 Ammeters—Not The Same.

June 2002: Wind Wing Chroming.

October 2002: Restoration Tip: 1949 60 Specials And All ‘49s With Parking Lamps: Painting Fine White Lines.

December 2002: Did You Know?…Early And Late Engines, Convertibles And Trunk Lids; Make Your Own Rubber Gaskets; Getting A Vacuum Antenna To Rise To The Occasion; Replacing Your Windshield Wiper Transmission Shafts;

Removing The Chrome Trim On A Club Coupe Rear Window;

March 2003: Did You Know?… Early ’49 Convertible Trunk Lids; Dealing With Those Six Volt Blues;

Windshield Wiper Restoration Tip; A Final (?) Word About Vacuum Antennas; Servicing Hydro-Lectric Pumps.

June 2003: Technical Help 4-U “Technical Assistance Hotline Numbers”; Some Tech Tips: Rear Shock Absorber Link;

Fix For Locked Up Brakes; Windshield Washer Pump & Nozzle Repairs; Hydro-lectric System; Auto Glass Source.

September 2003: Did You Know?…’49 Fuel Filters And Fuel Lines; Other Voices, Other Opinions: Hydraulic Brake Hoses.

December 2003: Those Other 1949 Cadillacs Or Stick Shift’s Last Hurrah;

Did You Know: Differences Between Series 61 And 62 2-Doors And 4-Door Cars In 1949.

March 2004: Our Readers Write: Fixing No Start Problem, Fuel System; Replacing A Front ’49 Shock Absorber.

June 2004: Two Tech Tips: Tighten Those U-Bolts (Rear Leaf Springs) & Car Won’t Start: Adjusting Neutral Safety Switch;

Filling Your Shock Absorbers With Fluid: Doing The Back Ones Ain’t As Easy As It Might Look.

September 2004: Viagra For Windshield Wiper Motors: A Tech Tip;

Overheard At The Grand National: Correct Gas Cap And Door Handle Escutcheon Gasket

December 2004: From The Busted Knuckle Garage: Slicker Sweepers (Aka Fuzzies) On Exterior/Interior Window Moldings;

Shocked Again: Adding Fluid To Shock Absorbers; Don’t Neglect Those Windshield Washers!

March 2005: Did You Know That: (Correct Procedure For Checking Head Bolt Torque); More On Those Other ’49 Cadillacs;

Restoration Tips From The Busted Knuckle Garage: Priming And Painting Small Bolts And Screws.

June 2005: Forty-Nine Engine Colors; Check Your Fuel Pump; More On Filling Your Master Cylinder;

’49 Times Index Of Articles (Technical And General Interest) March ‘01 To Dec. 2004; That Gas Filler Light.

September 2005: Mistakes In The ’49 Cadillac Shop Manual; More On Battery Cutoff Switch;

Trico Equipment And Service Specifications 1949 Cadillac.

December 2005: Taking Out Your 1949 Instrument Panel; If Your Horn Doesn’t Work.

March 2006: ‘49 Radiator Hoses; Detailed Specifications: Series 60, 61, 62 And 75;

Restoration Tips From The Busted Knuckle Garage: Restoring Your ’49 Cadillac Radio Speaker Grille.

June 2006: Tech Tip: Outside Door Handle Escutcheon Mounting Pads; More On Drooping Driver’s Outside Door Handle;

Series 61 And 62 Four-Door Sedans Compared To Series 60 Four-Door Sedans (Body, Trim, And Upholstery).

September 2006: ’49 Interior Paint Colors.

December 2006: Little Known Secrets Of Master Cylinder Rebuilding; Good Housekeeping In Your Car;

The 1949 Cadillac Vacuum System; Tech Tip: Larger Diameter Exhaust Pipe.

March 2007: Inoperative Cadillac Windshield Washers Can Be Easily Diagnosed And Serviced;

Unleaded Fuel And Exhaust Valve Seats; Tech Tip: The Clevis Pin On Your Master Cylinder.

June 2007: ’49 Cadillac Dimensions (Body); Replacing Motor Mounts; Locating The ‘Sweet Spot’ For Outside Door Mirror.

September 2007: Mini-Tech Tips: Have Your Brake Lights Failed? And Graphite Phright!

Fine Tuned Installation Of A Door Latch Repair Part.

December 2007: Keep Your Hats ‘Er, Sombreros On; Trunk Handle Problems; ’48 And ’49 Design Differentiation.

March 2008: Hood Bumpers; How To Remove/Replace A 1949 Cadillac Speaker Grille Without Taking Half The Dash Apart;

How To Fix Your Trunk Lock; Different Chrome Trunk “V” Emblems.

June 2008: Be Seen With Halogen Bulbs! Engine Of Change: Early And Late ’49 Cadillac Motors;

Deck Lid Designs; More On Trunk Lid “Vs”.

September 2008: 1949 Cadillac Carter 722S Carburetor Rebuilding Tips; Tech Tips: Sixty Special Dome Light

And Outside Door Handle Removal; Repairing Heater Control Valves; The Wooden Wheel Chock.

December 2008: Hydra-Matic Shifting Problems On My Coupe De Ville; Stopping An Oil Leak (Rear Main Seal);

Hydra-Matic Shifting Problems II: Shift Lever Slop; Did You Know That 60 Special Trunk Letters Are In 2 Pieces?

March 2009: Tech Tip: Chasing Down Those Elusive Exhaust Noises; Semi Tech Tip (Directional Signal Flasher);

Beware Non-Steel Head Gaskets; Mysterious Nether Noises In A ’49 (Rear Springs, U-Joints, Drive Shaft).

June 2009: Bias Ply Versus Radial Tires: A Never Ending Discussion; Conversion Of Air Cleaner To Use A Paper Element;

How To Hook Up Your 49’s Under Hood Heater Hoses; Come Blow Your Horn.

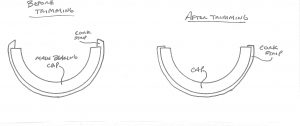

September 2009: A Better Way To Remove Coupe Door Glass: It Worked For Me; Removing An Outside Door Handle;

New Procedure For Testing Gas Gauge Tank Units; More On Bias Ply Versus Radial Tires.

December 2009: A Tail Light Tale; If Your Ammeter Is Neither Positive Nor Negative, But In Between.

March 2010: More Power, Mr. Scott (’49 Horsepower); Power Window Switches;

Another Tech Tip From The Busted Knuckle Garage: Hood Hinge Installation