by Art Gardner

If you replace brake lines and/or replace or re-do wheel cylinders, it can be a chore to get all of the air back out of the lines and cylinders. Here is a trick I came up with recently (this probably been used by lots of mechanics over the years, but it only occurred to me in the last month or so).

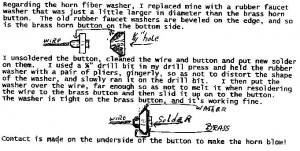

The idea is to fill the lines and the cylinders as full as possible with fluid before installing them. Recently, we replaced the rear lines, rear hose, F-to-R line, and rebuilt the rear wheel cylinders on my ‘50. To avoid endless pumping and bleeding of the brakes, I filled the cylinders as full as I could with fresh fluid, then attached the new (relatively short) steel lines and snugged them up. Then I filled the line and the cylinder the rest of the way by pouring brake fluid down the line, using a skinny awl to lead the fluid into the line like a reverse funnel. (See drawing on next page.) After filling the line and cylinders completely, we put a tight rubber cap on the end of the line and installed the cylinder/line. For the flexible rubber brake hose and the F-to-R steel line, we did basically the same thing.

We had removed the wheel cylinders to rebuild them and were installing new lines at the same time. So pouring the fluid into the lines up was no trouble. If you were doing it with the wheel cylinders still on the car, you could put a rubber hose on the end of the line and bend up the rubber hose to give you a vertical run to pour into and to provide the elevation change needed to force the air to rise up and out of the line. If you do it with the wheel cylinder still on the car, you might need to open the bleeder valve to let some of the air out that way. Since I had the lines oriented vertically with the wheel cylinders off the car, I didn’t need to open the bleeder and the air escaped up the line.

As a result, there was very little spillage and it didn’t take very long to fill the system or bleed the brakes. The net effect is that when we bled the brakes, there was very, very little air in the system that needed to be purged. We had a firm pedal almost from the start and the entire bleeding process only took about 10 minutes.