Some months ago the cylinder heads of my ‘49’s motor needed rebuilding, so I removed them and took them to a machine shop for repair. Taking off the cylinder heads with the motor in the car is not particularly difficult technically and the only special tool needed is a torque wrench. On the other hand, there are lots of parts to remove (and later re-install) and the heads are heavy, weighing more than 50 pounds each, so it can be a 2-person job.

The first task is to completely drain the coolant from the radiator and engine block. To do this, first raise the front of the car on jack stands. The motor has 2 small drain outlets on either side of the middle of the block, just above the oil pan. The Cadillac factory closed these off with small pipe plugs, which when removed usually results in the coolant flowing out in the wrong direction and making a mess. I replaced mine with drain cocks identical with the radiator drain cock, so I can put a rubber hose on each to direct the flow into buckets. While you are under the car, remove the oil dipstick tube and dipstick. Back on top, after lowering the car, unfasten one of the battery cables and remove the windshield washer bottle and bracket.

Next, remove the rubber fuel line. Then, drain the oil filter if you have one. Now, disconnect the upper and lower oil filter tubes at the oil filter end, leaving the tubes attached to the motor, and remove the oil filter. Unfasten the 4 bolts holding the thermostat housing to the water pump. Loosen the upper radiator hose clamp, turn the upper hose on the radiator outlet one quarter to one half turn to free the thermostat housing and remove the hose and the thermostat housing as a unit. Remove the fan belt, the fan and the generator along with its adjusting strap. Remove the lower radiator hose. Now the radiator and water pump can be unbolted and removed. I find it’s easier for 2 people to lift the radiator.

The next task is to remove the intake manifold. First, remove the air cleaner. Next, remove the accelerator linkage spring and unhook the accelerator linkage from the carburetor. Fold the accelerator linkage back against the firewall and hook it under one of the hoses or wires on the firewall. Disconnect the Hydramatic “kickdown” rod at the carburetor and transmission ends and remove it from the car. Disconnect the vacuum advance tube at both ends and remove it. Disconnect the manifold vacuum tube at the fuel pump end. Disconnect the automatic choke tube at both ends and remove it from the car.

Disconnect all wires from the coil (back-up light wire, coil power wire, coil to distributor primary and secondary wires) and tie them back to a hose or wire at the firewall. Disconnect the fuel pump to carburetor tube at the carburetor end. Tilt it up to a sufficient angle on the fuel pump that fuel doesn’t flow out but leave it in place. Loosen and remove the four bolts and four nuts with their washers that hold the intake manifold to the cylinder heads. Now the manifold can be removed with the manifold-to-fuel pump vacuum tube, carburetor and coil still attached. One person can lift it, it may be easier if you are two people.

Now the heads are almost ready to remove. Starting with the driver’s side head, unthread the spark plug cables from the loops on the valve cover on a late motor, or unfasten the spark plug wire conduits on an early motor, and tie them up to a hose or wire on the firewall. Remove the valve cover and set it aside. Remove the water hose that runs between the head and the defroster assembly. (I find it easiest to cut this hose, as it is hard to get a good grip to pull it off.) Unscrew the cylinder head ground strap at the firewall end. Now, unscrew the cylinder head bolts. Since the rocker arm assembly is full of oil, before removing it get a pan or other receptacle longer than the rocker arm assembly. With the pan ready to catch any oil, lift off the rocker arm assembly with its four bolts and set aside on the pan.

Remove the push rods. You must re-install the push rods with the same end toward the rocker arms and, preferably, in the same valve lifter. Note the shape of the push rod at each end. Punch holes in a piece of card board, number the holes with a pen or pencil and, to keep them organized, insert the push rods into the holes in numerical order with their top ends up.

Remove the 6 exhaust manifold bolts. Leave the exhaust manifold in place, since the crossover pipe is very rigid and will easily support the exhaust manifold after the head is removed.

Getting the passenger’s side head ready is similar. Unscrew the nut holding the wire to the water temperature sending unit. The voltage regulator can be left in place, but you risk banging the head into it. I usually unscrew the voltage regulator mounting screws and lay the regulator with its wires still attached on the nearby shock absorber with a rag underneath it. Deal with everything else in the same manner as the driver’s side head. The crossover pipe and exhaust pipe are very rigid and will support the exhaust manifold easily after the head is removed.

Before lifting off the heads, it’s a good idea to put some towels or other protection on the fenders and on the baffle in front of the radiator. If a head is stuck, tap it with a hard rubber hammer to dislodge it. You can grab the head by the water pump hole at one end and either the heater pipe, temp gauge sending unit or the ground strap at the other end. An assistant’s help can be useful at this point. Alternatively, you could use a “cylinder head lifting tool”, which are T-shaped tools that screw into the spark plug holes. You then pick up the head by the “T” crossbar. I have two I’ll lend to anyone who needs them. On the bench, remove the driver’s side head heater hose pipe, the passenger’s side head temperature gauge sending unit, both ground straps and the small pipe plugs at the rear of the passenger’s head and the front of the driver’s head.

Have your heads rebuilt in a reputable shop. It’s a good idea to have the re-builder install hardened steel exhaust valve seats so the engine can better cope with unleaded fuel.

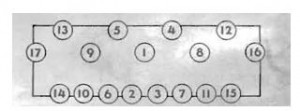

Re-install everything in reverse order. Head gaskets will say “TOP” on one side, so lay new ones thusly on the block with the guide studs engaged. Carefully lay the heads on the block, engaging the guide studs underneath it and ensuring that the gasket is not folded back or kinked. Torque the head bolts to 65-70 foot pounds in the order shown on the next page:

Re-install everything else using new gaskets. Be sure to put a bit of oil at both ends of the push rods. To make their installation easier, lightly cement new water pump gaskets to the front of the pump after scraping off the old gaskets. To facilitate exhaust manifold gasket installation, use a pry bar or large screwdriver to slightly pry the manifolds away from the head. Don’t install the intake manifold until all cylinder head bolts are torqued. Intake and exhaust manifold bolts and water pump bolts should be torqued to 25-30 foot-pounds.