Although my 49 steers precisely and easily, with no play or looseness at the steering wheel, my ’49’s steering gear box has always had a slow leak. I put a new gasket on the end cover a couple of years ago, but it did not improve things. Annoyingly, every month or so I’ve had to top it up.

After reading a CLC Forum thread on this subject and mulling over the suggested alternatives (all of which involve thicker oil or grease), I bought a ½ liter plastic bottle of Penrite Steering Box Lube for Vintage Cars (for anything without rack and pinion steering or power steering), an Australian-made flowable grease. It is sold in the U.S. by Restoration Supply Company in California and costs $17 per bottle, plus about $10 shipping. I ordered 2 bottles. When they arrived, I raised the front wheels off the ground, took off the left front wheel to provide better access to the steering box, and drained the oil from the steering box by removing the lower inboard bolt on the end cover. After replacing the bolt, I then removed the filler plug and squirted lube into the box by squeezing the bottle. To get it to settle in the box I had to turn the steering wheel from side to side a couple of times between squirts. One bottle was not enough to fill the box completely, so I had to use part of the 2nd bottle. It took several days before the lube totally settled, so I checked the box after every drive and topped it up. The box no longer leaks.

Category Archives: Differential Axles

YOUR REAR AXLE… SEALING WASHERS

In my article in the March 2011 issue of the Times entitled “Tech Tip: If Your Rear Axle Is Noisy”, in discussing leaks from same it was suggested that you “check the pinion seal as well as the large, round gasket where the differential meets the axle housing…”.

However, I neglected to mention that another source of leakage from this same area can be from around one of the 12 nuts fastening the differential assembly to the axle housing. Check the nuts to make sure that behind each one is a special copper sealing washer. If such a washer is missing or damaged, or if an incorrect ordinary steel lock (or flat) washer has been substituted, a leak may result.

IF YOUR REAR AXLE IS NOISY

The first thing to do is check the gear oil level in the differential. Lack of oil can cause a noise in the differential gears. It should be within a ½ inch of the upper hole and should be 80/90 weight oil. If oil is low, check your pinion seal as well as the large, round gasket where the differential meets the axle housing and the outside of your rear brake backing plates for leaks. If your pinion seal is leaking, unless you have the necessary tools and equipment it is best replaced by a professional, as the bearing and pinion nut need to be specially dealt with. The shop manual has details. The large gasket, sold by Olson’s Gaskets, can be replaced without special equipment by removing the differential, though be careful as it is very heavy.

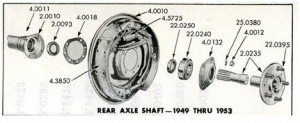

If there is a leak on the rear brake backing plates, (4.0010 in the diagram below.) ascertain whether it’s brake fluid or gear oil. If gear oil, there are oil seals on the outer ends of the axles (2.0093 in the diagram.), which when faulty will permit leaks of gear oil into the wheel area which will then drain out a hole where the axle meets the outside of the backing plate. To replace the seal, you must remove the axle, pull out the seal with a seal removing tool (or pry it out with the end of the axle) and drive the new seal all the way in with a large socket wrench or similar tool. (I can lend members my home-made tool if need be.) When you re-install the axle, spread some chassis grease on the rubber part of the seal so the axle doesn’t scrape and damage it. Such a leak can also be caused by a faulty gasket between the backing plate and the axle housing (4.0018). To replace this gasket, remove the axle, unscrew the hydraulic brake line from the wheel cylinder and remove the backing plate.

Check the axle bearings by driving the car when the noise is present. One way to tell if an axle bearing is causing the noise is to turn the car sharply in one direction and then the other. If the noise varies in intensity while doing this, it could signify a bad bearing. To replace an axle bearing (22.0240), you must remove the axle. It is not essential to remove and replace the seal at the same time, but it would be prudent to do so. The bearing must be pressed on the axle by a machine shop, being careful not to score the surface on the end of the axle that the seal rides on. (Now that cars are mostly front wheel drive, there are fewer auto machine shops that press on rear axle bearings.) These bearings and seals are sold by Olcar Bearings, Southern Pines NC for a reasonable cost, though you may find them at a modern auto parts supplier as they are standard for many cars. .

If you eliminate an axle bearing as the cause of the noise, the remaining possibility, of course, is that the noise is in the differential assembly. Assuming you’ve fixed any leak, if the noise is just a hum the differential can go for years without failing or causing any further problems, other than being annoying. (My own has been making such a noise for 20 years.) If you feel you must fix a noisy ’49 Cadillac differential, besides replacing the pinion bearing the shop manual recommends you not try to work on it and, in any case, does not tell you how to do so. Apparently, the problem is that some of the internal parts are held together by special pins that can only be removed by destroying them and some other parts nearby. The only possible fix is to replace it. Prez Joe Cutler has several ’49 parts cars and can probably sell you a good (quiet) used one.

INSTALLING UNIVERSAL JOINTS ON YOUR 49

by Art Gardner

If you start getting a “clanking” noise under your car, particularly when you step on or release the gas pedal, your universal joints may be worn and in need of replacement. I recently installed a set of U-joints on my car’s driveshaft. It took about 30 minutes to drive out the old ones and install the new ones. All you need to replace them is a screwdriver, a hammer, a large socket to support the end of the driveshaft and receive the “cups” and a 17 mm impact socket (I think 11/16) to use with the hammer to drive out the cups.

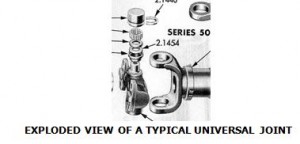

You remove the clips and drive one cup in (part at top left in the illustration below), which forces the opposite cup out. Then grab the cup that is jutting out with a pair of pliers and twist it until it is removed. Then tap the cross piece (part at lower left) back in to drive the other cup out the other way, then grab and remove the second cup with pair of pliers. Now just position the new cross in the yoke (part at lower right) and tap in the new cups, being careful to make sure that the needle bearings all stay in place. Once you have the cups tapped into position, lock them in place by installing the new C-clips (2.1440).

DID YOU KNOW THAT rear axle housing has a built-in air vent in the case

your ‘49’s rear axle housing has a built-in air vent in the case? I certainly didn’t

Some background: When I bought my 6107 25 years ago the differential pinion seal was leaking. The mechanic who replaced it looked everywhere on the axle housing and could not find a vent to the atmosphere. In addition to the motor, he said these were necessary on all housings that contained a rotating mechanism in gear oil, including the rear end and transmission, to prevent oil pressure building up which can cause leaks and the oil to foam (which reduces its ability to lubricate). To rectify this he drilled and threaded a hole above the right-side spring and screwed in a small venting valve he took from a junked car.

I had no further problems in this area until recently, when my rear axle housing started leaking gear oil on the right side at the junction of the axle housing and the passenger’s side brake backing plate. (There’s a special channel at that point to direct away from the brake shoes any gear oil leaking past the axle seal.) It was a small leak, but it became very annoying to see it whenever I climbed under the rear of car for any reason. I replaced the axle seal, and even installed a spare axle shaft on the assumption that might help, but the leak persisted.

Thinking the leak might be due to a crack or flaw in the axle housing, I bought a used one from ’49er Joe Cutler and started the formidable task of removing and replacing it. However, while cleaning up my new purchase I noticed a slit-like hole on the upper right of the back of the round part of the housing, which is the long-lost air vent. (See arrow in photo on next page.)

I then checked out the same hole on the housing still in my car to find that it was barely visible and completely clogged with dirt. I cleaned out the hole with a small knife which stopped the leak. Problem solved.

MYSTERIOUS NETHER NOISES IN A 49

During the 24 years I’ve owned my 6107, it has been afflicted at least twice with a mysterious noises emanating from somewhere underneath the car. In both instances, though I continually tried to figure out where the sounds were coming from, and asked every knowledgeable car guy of my acquaintance for their advice, it was only when I finally consulted a local shop that specializes in this sort of thing that the problems were resolved.

The establishment in question is Doraville Driveline and Spring, located not far from my house in the Atlanta suburb of that name. (No telling who “Dora” was.) DD&S is one of those old time establishments, kind of mysterious and dark, filled with lots of neat looking older machinery and staffed by a bunch of guys who live and breathe drivelines, springs and related components.

The first set of noises that existed from the time I bought the car until 16 years ago was a cacophony of creaks and groans that came from somewhere underneath whenever I started out from a stop or took my foot off the accelerator pedal. It was all the more embarrassing when a sound video made at the CLC Grand National in Lancaster PA in 1993 had a shot of my car starting to roll with the aforementioned noises loud and clear. Chapter member Bob Knutson, who lives nearby, recommended DD&S, whose manager told me that replacing my rear leaf springs would cure all these ills. A new pair was ordered from the Triangle Spring Company in Pennsylvania and then installed. Following this operation, my ’49 stayed quiet for some years.

Then, about a year ago, my car’s gear shift lever began to rattle at high speeds. (Manual transmission ’49s like mine don’t have the same anti-rattle spring for the gear shift lever as Hydra-matic cars.) Taking a shot, I replaced the motor mounts, then took out the clutch which I had rebuilt and balanced, but the annoying rattle persisted.

When I drove to the Grand National in Cherry Hill, New Jersey last August, not only did the rattling become worse, but it was joined by squeaks and clanks from under the car that would come and go for no apparent reason. Though these sounded like a discordant symphony orchestra, looking under the car did not reveal anything amiss. As you can imagine, every CLC’er present at the Grand National whose opinion I sought had a different theory. One evening, with my patient wife holding the tools and several other GN attendees supervising, I took off both rear brake drums to check for broken brake springs, but they were fine. I then tightened all the rear stabilizer and exhaust system bolts. Nothing changed.

Meet Chairman Jack Hotz then arranged an appointment for me and my ’49 at his favorite garage, Majic Auto Repair in nearby Haddonfield. Raising the car on his lift, Majic’s owner could not detect a definite fault, though he was convinced the problem was with either the driveshaft or the clutch throwout bearing.

Back home, I finally did what I should have done in the first place and drove the car over to Doraville Driveline and Spring. Like Majic back in NJ, the manager thought the problem was the driveshaft, so he climbed under the car to closely examine it. He said no one part of it was in very bad condition, but the front and rear universal yokes and both universal joints were somewhat worn, which cumulatively added up to lots of wear and caused all the sounds. Also, the driveshaft tube itself was full of dents and dings, rendering it out of balance and causing the gear shift lever rattle.

A phone call bought a NOS front yoke from Ted Holcombe Cadillac Parts which I had shipped to DD&S. Meanwhile DD&S had in stock a used dent-less driveshaft tube with a perfect rear yoke along with new universal joints. DD&S put all these together. When I installed the rebuilt driveshaft in my Cad and took it for a ride all its noises were gone. Another lesson learned.